Product info

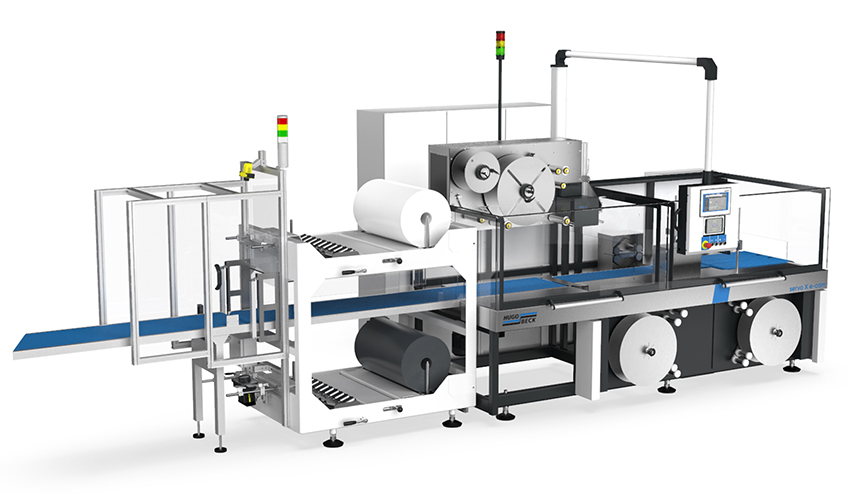

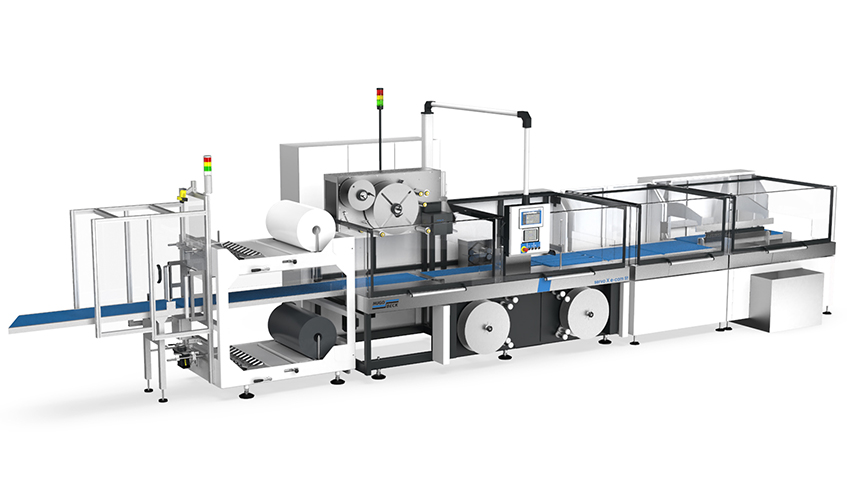

[ 1 ] Servo X e-com (fit)

CONTINUOUS FORM FILL AND SEAL MACHINE ( flowpack machines )

FILM PACKAGING FOR E-COMMERCE, MAIL ORDER AND LOGISTICS

- ์ ํ ๋ช : Servo X e-com (fit)

- ์์ฐ์ง : HUGO BECK ( ๋ ์ผ )

- ์๋ด๋ฌธ์ : 031-790-4141~5

Servo_X_e-com

Servo_X_e-com_fit

์ฅ๋น์ฌ์

| TECHNICAL DATA | ย |

| Product infeed | manual as standalone/automatic in line |

| Product size | L: 100 โ 600 mm, W: 150 โ 500 mm, H: max. 200 mm |

| Capacity | Servo X e-com: approx. 3000 cycles/h Servo X e-com fit: approx. 1800 cycles/h |

| Film | Upper/lower film: PE flat film 30 โ 100 ฮผm, PCR film (> 80 %) |

์ฅ๋น์ค๋ช

With the servo X e-com you are ideally equipped to meet the demands of film packaging for the e-commerce, mail order and logistics sectors.

Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging for example, the servo X e-com packs goods with a minimum use of film and automatically adjusts the film bags with four sealed sides to the product’s length as standard.

To support the precise fitting of shipping bags, the servo X e-com fit model also adjusts the bag size to the product’s width so that the machines fully automatically adjust to varying product sizes during the packaging process.

Furthermore, packaging with upper and lower film enables a greater scope for branding, for example with two-tone shipping bags.

Additional options include the ability to add an easy-opening perforation to the bags as well as inserting a double-sided adhesive tape for resealing a bag for returns.

์ฅ๋นํน์ฑ

โข Tight bag packaging with lowest possible material use and optimum processing of recyclable

ย films made from mono-material or recycled material

โข Each bag size is automatically adapted to the product’s length as standard, and also to t

ย he product’s width as an option

โข Integrated scanner with a controller for product detection and creation of a shipping label,

ย which is continuously dispensed directly onto the film without an applicator

โข As an option, easy-opening perforation and inserting of a double-sided adhesive tape for

ย resealing the bag

โข As an option, “Easy Splice” โ film change by thermal welding

โข Optimised user-friendliness and accessibility

โข Connection to ERP or control systems

โข Industry 4.0 Ready

โข Optional monitoring, analysis and visualisation of machine and operating data via

ย the Hugo Beck Cockpit