Product info

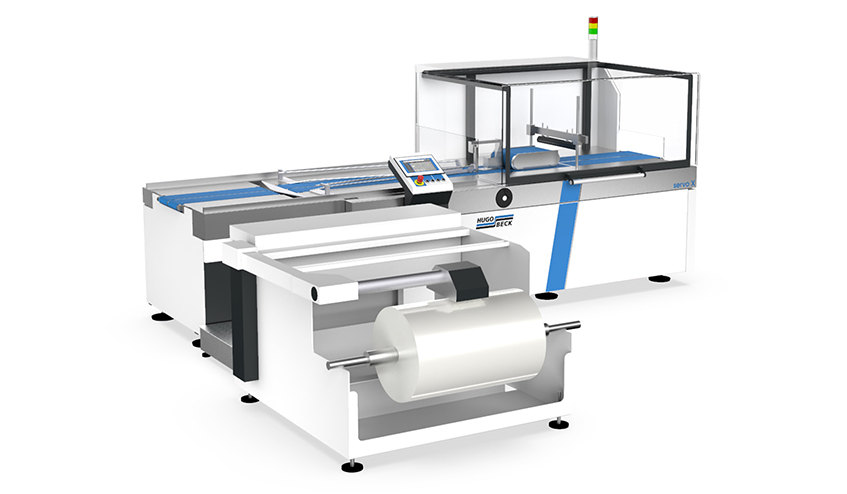

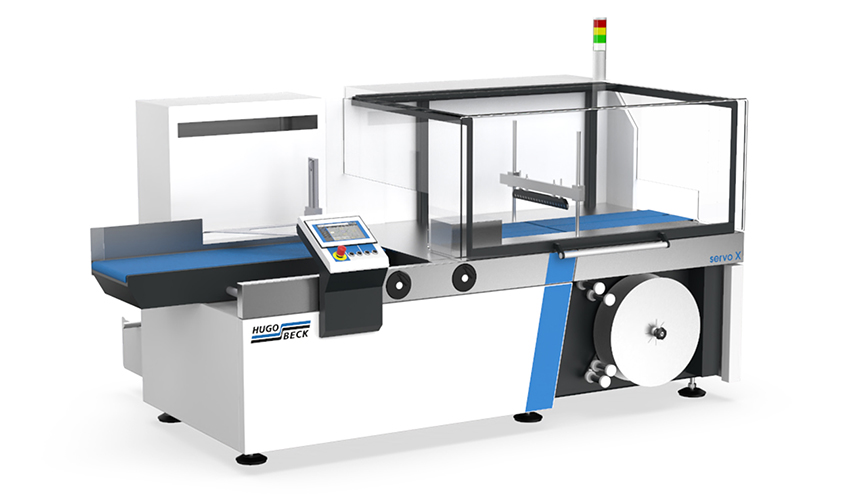

[ 2 ] Servo X

CONTINUOUS FORM FILL AND SEAL MACHINE ( flowpack machines )

THE MODULAR

HIGH-END ALL-ROUNDER

- ์ ํ ๋ช : servo X

- ์์ฐ์ง : HUGO BECK ( ๋ ์ผ )

- ์๋ด๋ฌธ์ : 031-790-4141~5

Servo_X_advance_top_overlap_side_sealing

Servo_X_step_belt_side_sealing

Servo_X_top_overlap_flat_film

Servo_X_conveyor_belt_side_sealing

Servo_X_chain_bottom_overlap

Servo_X_chain_side_sealingp

์ฅ๋น์ฌ์

| TECHNICAL DATA | ย |

| Product infeed | manual as standalone/automatic in line |

| Film | All types (centre-folded film and flat film) such as PE, PO, PP, Bio films |

| Product size | L: from 45 mm, W: 10 โ 450 mm, H: max. 250 mm |

| Capacity | Five performance classes up to 15,000 cycles/h |

| Versions | Side seal or bottom cut seal, overlap on top, bottom overlap with or without sealing/ionisation |

์ฅ๋น์ค๋ช

servo X Form Fill and Seal machines are available in five performance ranges and numerous

variants. They cover the broadest possible range of horizontal film packaging applications for

various industries โ and all this with maximum modularity.

The machines can be configured individually and thus meet all requirements for the desired

performance or type of packaging. Depending on the machine variant, several packaging

styles can be flexibly produced with one machine.

Whether chain infeed or infeed conveyor, servo X machines win over with their continuous

packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides

high performance, this enables extremely tight-fitting and precise packaging with a saving in film

of up to 15 %. This ensures that the film packaging’s excellent appearance is unrivalled.

์ฅ๋นํน์ฑ

โข Minimum product spacing for maximum film saving thanks to precision synchronisation of

ย the transverse sealing unit and product

โข Optimum film feed for processing the most diverse of film types and grades

โข Siemens TIA Portal and free remote service

โข Smart user guidance via CoPilot and touch screen

โข Maximum serviceability and maintainability thanks to perfect access and numerous

ย maintenance-free components

โข Easy line integration and connectivity with higher-level systems; Industry 4.0 Ready

โข Optional monitoring, analysis and visualisation of machine and operating data via

ย the Hugo Beck Cockpit